Occupational Hearing Conservation: A Mobile Audiology Business Plan

Lexi Rozycki & Kiersten Steinke

Aspiring private practice owners don’t consistently receive formal business education from university audiology training programs. For those who do, it is often limited to a single course. Therefore, opportunities to receive practical advice from seasoned practice owners offer invaluable training for students considering private practice.

This article illustrates the painstaking details of creating a business plan for an industrial audiology practice. It serves as a good example of the attention to minutiae needed to get a loan approved by a lending agency. It also demonstrates how the owner must carefully plan for future growth and make decisions that are financially viable.

We thank Nancy Green, Au.D. and Larry Schmidbauer, Au.D. for allowing us to publish a portion of their thoughtful feedback on this proposed business plan. Their input can be used by the authors to strengthen the plan and create a solid framework for success.

Elevator Pitch

Grand Rapids, Michigan is home to various manufacturing industries including metals, plastics, automotive, and food processing. Sound level measurements in manufacturing measure in the range from 81-115 dB(A) which can put employees at risk of noise-induced hearing loss and other auditory injuries, but there is a shortage of industrial audiologists nationwide.1,2 A mobile audiology clinic focusing on tailoring hearing conservation programs (HCP) to businesses’ specific needs and preventing noise-related work injuries has the potential to make a profit within the first three years of business. This business plan will outline the structure of this mobile audiology clinic.

The Team

The team consists of an audiologist who is a member of the National Hearing Conservation Association (NHCA) as well as two industrial hygienists. The audiologist and industrial hygienists are certified by the Council for Accreditation in Occupational Hearing Conservation (CAOHC). The audiologist is dedicated, personable, and highly knowledgeable about hearing loss prevention and preservation practices and has years of experience conducting industrial hearing screenings and fitting custom hearing protection. In general, the audiologist oversees the noise surveys, marketing, creating, and developing the HCP, education, and training of employees, and assisting with the hearing testing when needed. One industrial hygienist oversees industrial testing and earmold impressions. The second holds these roles but also helps with tracking audiograms. Lastly, we have an office staff member who oversees the scheduling and bookkeeping and who will work remotely. The hearing conservation program services include noise monitoring, a written report of the noise survey, noise mapping, occupational hearing evaluations, tailored hearing conservation programs to the company’s needs, and custom hearing protection.

Market Summary

We have decided to base our mobile audiology business out of Grand Rapids, MI for a variety of reasons. Twenty-one percent of jobs in Grand Rapids, Michigan are manufacturing jobs which is twice the national average for large metro areas.3 In 2020, there were 119,000 manufacturing jobs in the city which means a large portion of the population is at risk of damaging their hearing. Additionally, Grand Rapids is home to industry leaders in a variety of manufacturing sectors, including some of the nation’s largest industry concentrations in metals, plastics, biopharmaceutical, medical devices, production technology, automotive, office furniture, and food processing.4 Additionally, there are also eleven music venues in Grand Rapids we could work with to fit custom hearing protection.5

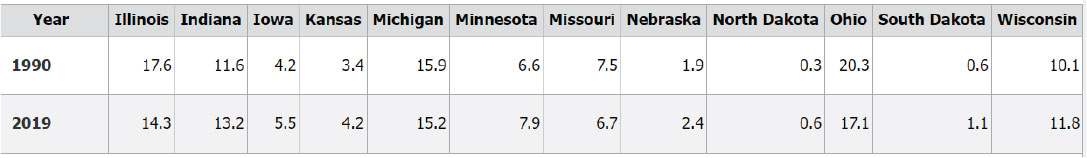

While there has been a decrease in manufacturing throughout the United States in the last few years, Table 1 from the U.S. Bureau of Labor Statistics.6 shows the opposite trend in the Midwest. This increase is seen in the following Midwest states: North Dakota, Indiana, Minnesota, Iowa, South Dakota, Kansas, Nebraska, and Wisconsin.7

Table 1. State Share of Manufacturing Employment in the Midwest region, 1990 and 2019 (in percent)

Additionally, as shown in Table 2, the Midwest and particularly Michigan has a large number of manufacturing companies employing a substantial number of workers.

Table 2. Number of Manufacturing Companies and Workers by State

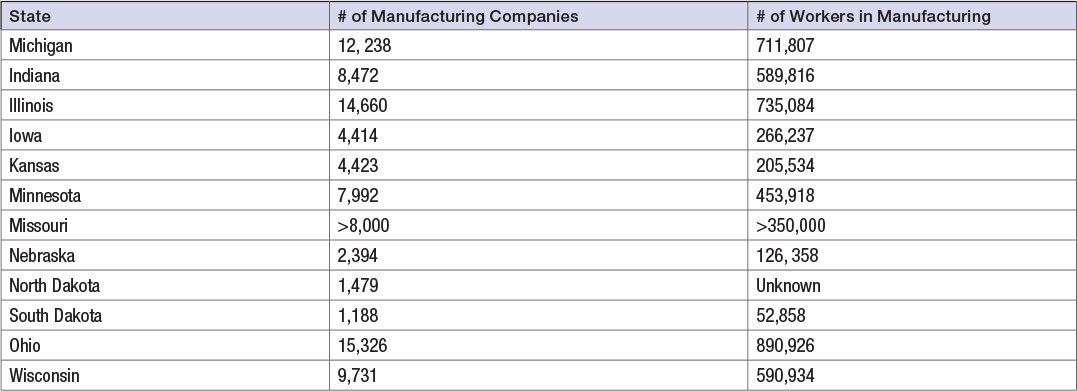

Due to the numbers and statistics listed above, we will aim to primarily service Michigan, Indiana, Illinois, Ohio, and Wisconsin by year three. These states are geographically close and have the highest number of manufacturing companies and workers. Additionally, we may travel to Minnesota or Missouri if we are contacted by a manufacturing company in one of those states.

Image: Geographical Area for Services

Despite the national trends showing there is an overall decrease in manufacturing; it is required for all individuals in manufacturing to follow OSHA requirements for a safe workplace. This means that our services are required by all manufacturing companies in the Midwest that meet OSHA requirements. Additionally, there has been an increase in protective health measures within society, so we are adopting this idea and promoting healthy hearing practices backed by OSHA standards to create tailored hearing conservation programs for manufacturers.

Competitive Landscape & Advantage

According to Green,2 while there are around 30 million workers who are exposed to damaging levels of sound, there are just ~200 audiologists who provide industrial audiology services nationwide. Consequently, there is a tremendous need for industrial audiologists nationwide — and only one other audiologist in Grand Rapids performs industrial tests. This audiologist does not serve as a direct competitor to us because workers must travel to them for the hearing test, while our mobile audiology clinic is more convenient and efficient for the workers. VanWyk Risk Solutions in Grand Rapids provides custom risk solutions to businesses and has a whole resource page about how to protect workers from workplace hearing injuries.9 Instead of viewing VanWyk Risk Solutions as a competitor, we could contact them to act as a referral system to encourage businesses to use us as their hearing conservation specialists. Our business utilizes Sensaphonics, a company based in Chicago, IL that specializes in in-ear-monitor systems and custom ear plugs, and was founded by audiologists.

Sensaphonics custom hearing protection uses medical grade silicone and is exacting about the ear impressions they take to make the best-fit custom plugs. Audiologists hold extensive knowledge about sound levels, noise-induced hearing loss, and ways to protect against noise-induced hearing loss, which will be to our advantage over competitors. Covered OSHA businesses must adhere to OSHA standards. Therefore there will continue to be a need for hearing conservation programs for many years to come. This means that employers must keep abreast of hearing evaluations and reduce workplace injuries related to noise.

Goals and Objectives

What follows are key milestones that we expect to reach at the end of each of our first three years in business.

End of Year One

- Test one to two companies per month by establishing ourselves in Grand Rapids, Michigan

End of Year Two

- Add a second mobile practice (another “location”)

- Double the number of company employees

- Test three to four companies per month

- Expand to Indiana and Ohio

End of Year Three

- Add a third mobile practice (another “location”)

- Add another audiologist, two industrial hygienists, and one office staff

- Expand the company to Illinois and Wisconsin

- Plan to have the largest noise survey and hearing conservation program backed by OSHA protocols in the Midwest

- Be profitable and pay off our small business loan

Marketing Strategy

How will our business be marketed?

Our marketing strategy will begin with our vehicle, which will be vinyl wrapped with our logo, mission statement, and contact information. According to the Out of Home Advertising Association of America, vinyl wrapping can be the most effective and efficient form of out-of-home advertising, reaching consumers at a lower cost per thousand impressions than any other form of advertising. Vinyl vehicle advertising costs approximately four cents per thousand impressions, which is significantly lower than other forms of advertising (outdoor signs cost ~$3.65 per thousand impressions, and newspaper ads cost $19.70 per thousand impressions).10

We will be creating a website that advertises our mission statement, the importance of noise conservation, the services we provide, and contact information for a phone consultation. This will have the same logo and aesthetic as our mobile practice vinyl wrapping. Along with the website, we will be utilizing Facebook, Twitter, and Instagram social media platforms to create weekly marketing posts.

Additionally, we will be advertising in IndustryWeek Magazine, an online magazine, that markets to 760,722 subscribers whose companies range from 100 to 100,000 employees.11 IndustryWeek is a business publication that focuses on manufacturing, with its readers consisting of corporate and executive management (43% of readers), operations, production, and plant managers (31% of readers), and engineering, R&D, and design and technical management (18% of readers). Advertising in IndustryWeek will help launch our services to a broad audience and position ourselves within the manufacturing industry.

How will the patient caseload be developed?

In the beginning stages, we will develop a caseload by reaching out to industries in the Midwest, such as factories, power plants, oil rigs, and other industries with a large amount of noise exposure. We will be conducting our own searches of these companies and contacting them via email or phone to introduce ourselves, the business, and provide a cost estimate. We also hope to gain business from the ad placed in IndustryWeek and referrals received from Van Wyk Risk Solutions.

Services and Pricing Structure

Noise Survey and Mapping: $1,00012

The first and most important step of a hearing conservation program is to measure the noise levels and workers’ noise exposure during the workday. This will help identify hazardous work locations and specific employees who are exposed to hazardous sound levels by acquiring personal time-weighted average (TWA) samples throughout the facility, even in areas that may not appear to be particularly noisy. Noise sampling needs to be conducted every three years, or any time there is a change in facility processes or equipment.13

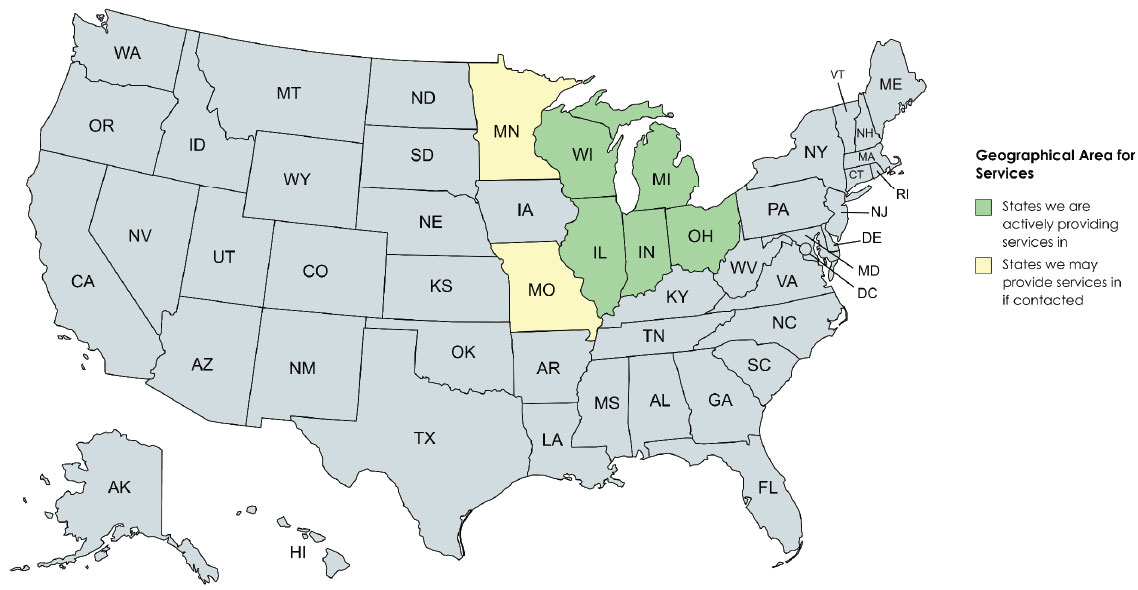

A noise map allows the HCP team to identify noise levels that contribute to a worker’s cumulative exposure and indicate where noise reduction efforts are needed to reduce the possibility of noise-induced hearing loss. To create a noise map, a floor plan of the workplace is used, and specific noise readings are logged on the floor plan. Few workplaces have steady noise so the sound level measurements will be obtained at three different times per location and averaged and a range of noise will be recorded.13

Image 2. Example of Noise Mapping14

Occupational Hearing Evaluations and Customized Hearing Conservation Program: $200/employee/year.15

The Occupational Safety and Health Administration (OSHA) requires employers to establish a hearing conservation program to educate employees on noise-induced hearing loss when employees are exposed to 85 dB(A) or greater for an 8-hour timeweighted average (TWA).16 The education under a hearing conservation program includes information about the effects of noise on hearing, the different types of hearing protection and their purpose, and the importance of audiometric monitoring. Audiometric monitoring includes baseline and annual audiograms as well as notifying the required OSHA personnel of the results. If a Standard Threshold Shift (STS) is identified, then a retest will need to be scheduled within 30 days of the annual audiogram to determine if there is a shift in hearing. Records will need to be kept regarding noise exposure measurements, audiograms, and data on hearing loss due to occupational noise exposure.

Custom Hearing Protection: $225/worker

Research shows proper fit hearing protection can protect against noise-induced hearing loss which can occur at 85 dB(A) over an 8-hour time-weighted average. In comparison, the normal level for a typical conversation is 60 dB. When noise levels exceed 100 dB, a person can experience hearing damage in as little as 15 minutes.17

There are many consequences of occupational noise exposure including noise-induced hearing loss and other auditory injuries such as tinnitus, hyperacusis, and misophonia which can affect productivity and increase the company’s liability. According to current OSHA regulations employers have a legal duty to “prevent or reduce the risks to health and safety from exposure to noise at work.”18 While the best way to protect against noise-induced hearing loss is to eliminate noise hazards, this change is not possible in many occupational settings. With this in mind, well-fitted hearing protection is crucial.17 Under OSHA regulation, hearing protection should be readily available to employees that are exposed to levels of sound at 90 dB(A) or more over an 8-hour TWA.16

While non-custom hearing protection is the standard among industrial and manufacturing workers, there are many benefits to providing all employees with custom hearing protection. Custom hearing protection is more effective than other forms of hearing protection because of the tight fit. The strength of the filter can also be adjusted due to the worker’s needs and sound exposure which benefits the employee and their hearing.19 Taking an earmold impression of the employee’s ears allows the hearing protection to be more comfortable than universal fit earplugs. One of the biggest complaints from employees is that hearing protection devices are not comfortable, and providing customs to employees would eliminate this barrier.19 Finally, custom hearing protection is a better value than universal earplugs. Universal earplugs are one to two-time use, while custom devices can be used repeatedly which prevents employers from repeatedly purchasing earplugs.19 The patient, or in this case, the worker will benefit from the custom hearing protection by reducing their risk of noise-induced hearing loss which in return prevents the business from having to report a workplace injury.

Part of our plan is to provide custom-fit hearing protection to employers at slightly above the cost from the manufacturer. In the long term, this will provide a higher investment in the health and wellness of their employees. To ensure the value of our services, the earmold impressions will cost $100 dollars per employee, and the hearing protection will cost $125 per employee, which are combined creating an overall cost of $225 per employee.

Overall Summary of Services and Costs

- Noise survey and mapping: $1,000

- Occupational Hearing Evaluations and Customized Hearing Conservation Program: $200/worker/year

- Custom hearing protection: $225/worker

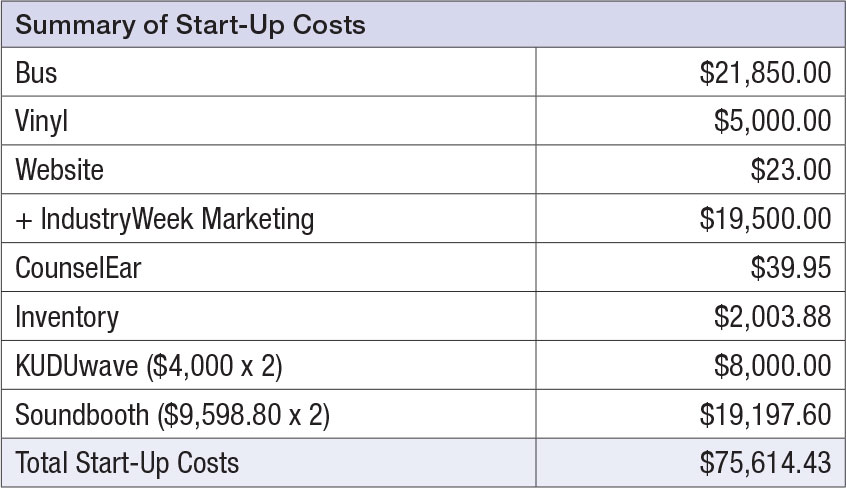

Start-Up Financing and Start-up Costs

To start our business, we will be taking out a small business loan of $100,000 with a four-year loan term and a 6% interest rate. This will equal a total principal of $100,000 and a total interest of approximately $24,000 over that term. Additionally, this will result in forty-eight monthly payments of $2,584, which will be calculated into the ongoing costs per month.

The Mobile Practice Vehicle and Upgrades

For our mobile practice, we wanted an affordable and reliable vehicle that could be renovated into a small audiology practice that contains an OSHA-approved sound booth and storage for ear impression material and sound level measurement equipment. We considered three different types of vehicles for our practice: a tiny home, a box truck, and a school bus. Based upon our research, we determined a used 2010 Chevrolet Thomas 8+2 Thomas ADA Type A School Bus would best suit our needs, which cost $21,850. The school bus, which is ADA accessible, is large enough for external marketing, a sound booth, and equipment storage.

For exterior upgrades to the bus, we will be using a vehicle wrap for exterior marketing. There is often a misconception about car wrapping that it is used for large companies for vehicle fleets, however, there are many benefits to choosing vinyl wrapping over a traditional paint job. Vinyl wraps are a cost-effective solution in comparison to the price of painting a vehicle and provide the vehicle with a new appearance. The vinyl wrap will include our business’s name, email, and company phone number. The average cost of a vinyl wrap is $1500-$5000, and we will be using the high average of $5000 for our start-up costs. We plan to remove unneeded seats ourselves on the interior of the bus (while keeping seats for our two employees) and using the bus to transport all the equipment which reduces interior renovations.

Equipment

We plan to use two audiometers and two collapsible/mobile sound booths to start our mobile hearing conservation practice. We will be purchasing KUDUwave audiometer which connects to a PC and uses an ambi-dome to attenuate ambient noise and has the ability to perform air and bone conduction, speech reception thresholds, word recognition testing, speech-in-noise testing, central auditory processing testing, masking for both air and bone conduction, and extended highfrequency audiometry. The KUDUwave system can be automated or manual, with in-person or remote testing in synchronous or asynchronous modes. The KUDUwave features the Ambi-dome headset, which consists of circum-aural earphones connected with insert earphones to increase sound attenuation and measure the ambient noise levels. Testing is only performed during periods where ambient noise falls below the noise floor limit. Per system specifications, the combined earcup and ear-insert technology provides 31-52.3 dB of attenuation while operational background noise levels range from 50 to 70 dB SPL which allows testing down to 0 dB HL from 125-8000 HZ. Additionally, reports on the validity of the KUDUwave system have found that average air conduction thresholds measured in adults were within 5dB and well within test/retest reliability.20 The KUDUwave costs approximately $4000.00.21 We will be purchasing two KUDUwave audiometers and using the automated air conduction threshold testing feature to test one employee while the industrial hygienist sets up and instructs the next person.

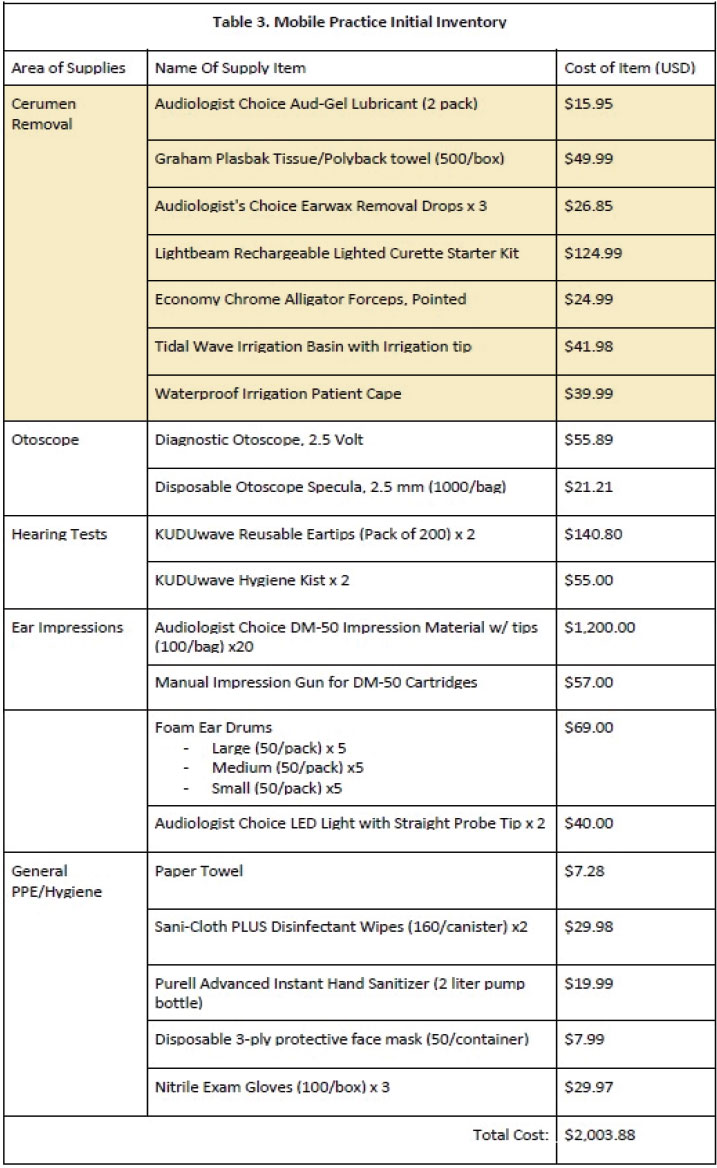

Table 3. Mobile Practice Initial Inventory with Projected Costs

Despite the KUDUwave advertising they are a booth-less audiometer system, we want to ensure all tests meet all ANSI and OSHA standards for hearing conservation programs. Due to this, we will be purchasing two portable sound booths via Whisper-Room via the Audiology Basic Package. As advertised, the WhisperRoom Audiology package sound booths meet ANSI/OSHA standards, as well as being portable and easy to relocate. The Audiology Basic Package includes the MDL 4872 S, a single-wall booth with dimensions of 4' 2" x 6' 2" x 6' 11". The booth comes with ventilation, a door window, and cable passages. Based on the WhisperRoom product catalog, the cost of the Audiology Basic Package is $9,598.80. Additionally, we will need two booths, as we will be conducting two occupational hearing tests at the same time.22

Inventory

Since we will be providing hearing screenings, occupational hearing tests, and custom earmolds, we will need some supplies. Below is a table of basic inventory items we will need when visiting sites, and how much we will purchase at the start of our company.

We will be creating our website using Squarespace, using the business model plan for $23/month which allows us to save money by not hiring an individual to create the website for us and allows us to make edits or changes at any time.

Marketing

We will be advertising in IndustryWeek’s ENewsletter under the sponsor exclusivity section (only one paid ad is allowed per each ENewsletter) and using an above-the-fold placement (ad placed at the top of the newsletter). The ad includes a 40-character headline, 75-word URL, and a 180x150 pixel logo. We will be placing an ad every Tuesday for 6 weeks, which will total $19,500.23

Record Keeping and Documentation

For record keeping and documentation, we will be using CounselEar. CounselEar is designed for Audiology clinics and clinicians to customize professional reports, chart notes, fax cover sheet, cover letters, and medical clearance forms, as well as the ability to fax and email reports directly from CounselEar. CounselEar is HIPPA Compliant and can be used to meet our need of storing occupational health audiograms, as well as manage the hearing conservation program. CounselEar is approximately $50 per clinic, with no upfront cost and no contract to sign.24

For record keeping and documentation, we will be using CounselEar. CounselEar is designed for Audiology clinics and clinicians to customize professional reports, chart notes, fax cover sheet, cover letters, and medical clearance forms, as well as the ability to fax and email reports directly from CounselEar. CounselEar is HIPPA Compliant and can be used to meet our need of storing occupational health audiograms, as well as manage the hearing conservation program. CounselEar is approximately $50 per clinic, with no upfront cost and no contract to sign.24

Projected Labor Costs

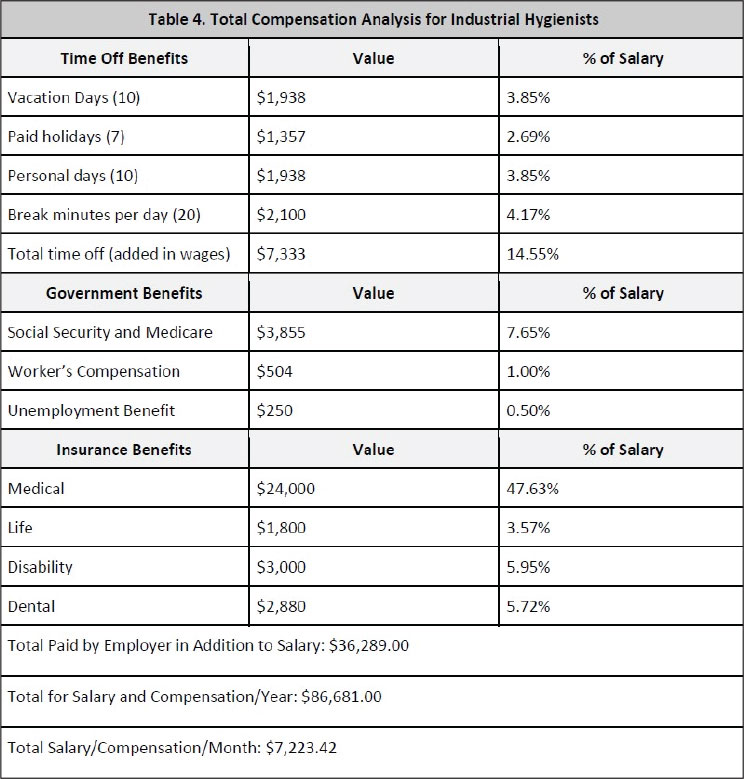

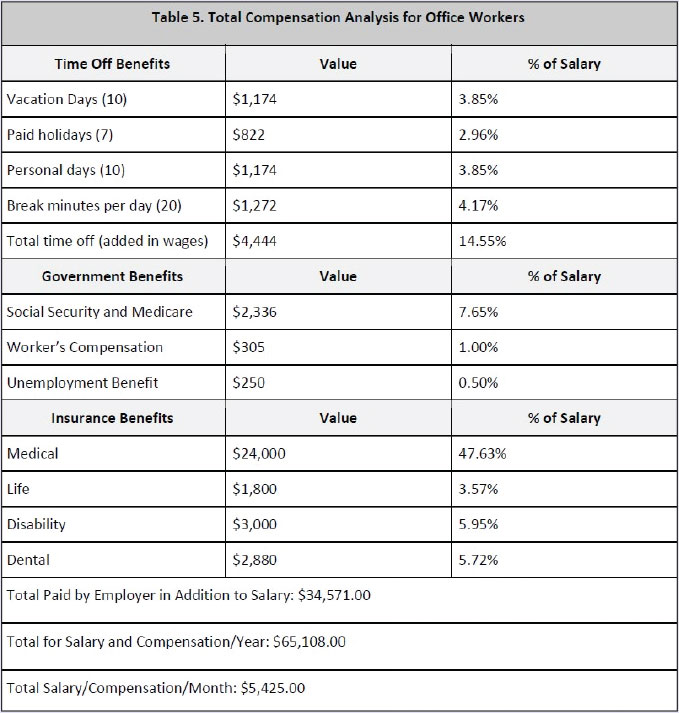

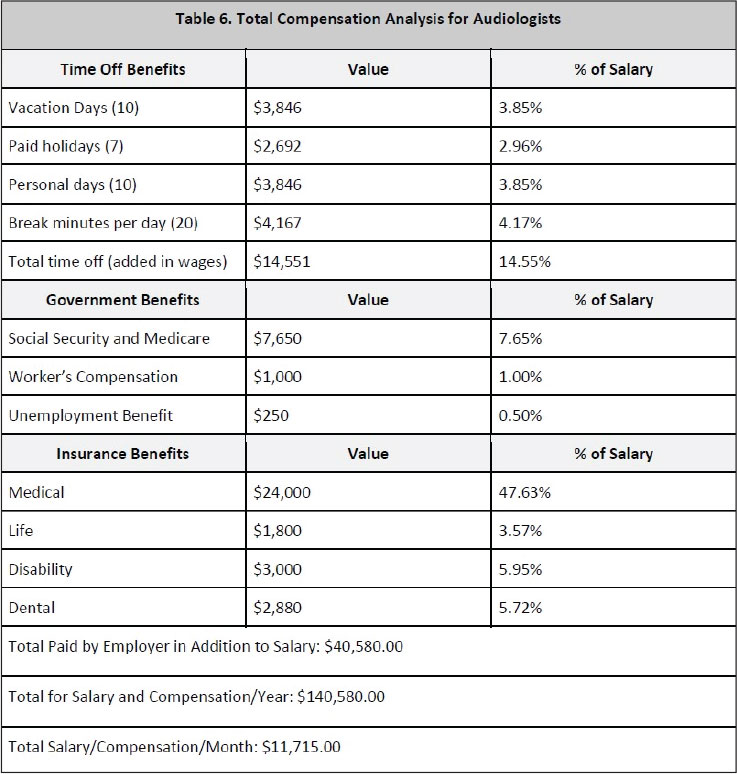

There are three types of employees associated with this practice, each of which has their own individual cost structure. Table 4-6 provide an analysis of the labor costs associated with each employee type.

Salary of Employees (Plus Cost of Benefits)

As of Apr 30, 2023, the average annual pay for an Entry Level Industrial Hygienist in the United States is $50,392 a year. This is equivalent to $969/week or $4,199/month.25 Table 4 is a thorough breakdown of all compensation related to employment of the industrial hygienists in this practice.

For the office staff, the average national salary is $30,537 per year. This is equivalent to $587/week or $2,544/month.26 Table 5 is an estimate of the costs associated with employing office workers in this practice.

The practice will start out with a $100,000 annual salary for the audiologists, which is equivalent to $1,923/week or $7,692/ month. Table 6 is a detailed projection of the compensation for the audiologists in this practice.

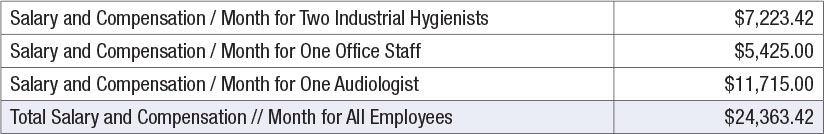

Table 7 is a summary of projection of costs associated with compensation of staff (costs of labor).

Table 7. Summary of Total Compensation for all Employee Types

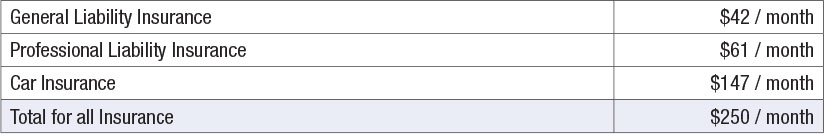

Insurance

We will be purchasing general liability insurance for our business, professional liability insurance, worker’s compensation insurance, and car insurance for our mobile practice. This will all be necessary to protect the business, the workers, our products, and equipment. Table 8 is an estimate of all insurance costs related to the operation of the practice.

Table 8. Insurance Costs

Vehicle Gas and Maintenance

In our first year of business, we plan on serving customers primarily in Michigan, as we are located in Grand Rapids which will allow us to have less travel time and commit to servicing businesses. Based on the travel, we estimate an average of $100 in gas per site visit. Once we expand to the other states (as outlined in Year 2 and 3 goals), we estimate an average of $200-300 in gas per business. For the purpose of the financial roadmap, we will be using $250 as our cost of gas per business served.

Additionally, we will be performing yearly maintenance on our minibus, which will equate to $1,700 per year. This includes four oil changes, air filters, fuel filters, two tire rotations, A/C service, brake, and other miscellaneous services that may be required.27

Cost and Revenue Projections

Here we estimate the ongoing costs and projected revenue associated with servicing one company in Year 1 of business operations.

Overall Summary of Ongoing Costs Per Month with One Company Serviced for Year 1

- Total salary and compensation/month for all employees: $24,363

- Total for all insurance: $250

- Total bus cost: $241

- + Restock supplies: $1,500

- Room and board: $3,080

- Business loan payment: $2,584

- Food stipend: $2,100

- Website and CounselEar subscriptions $80

Total: $34,198 per month

Annual estimated costs: $410,376

Average Revenue Per Business Serviced

Based on statistics from the U.S. Bureau of Labor Statistics, we will be using an average of 250 employees per manufacturing company. Although this number will fluctuate per company, we believe that 250 employees is representative of most of the companies we will be servicing and will provide a valid baseline for our revenue projections.28

With this number established, we will first be reviewing the services (and the cost of these services) that our mobile practice is providing:

- Noise survey and mapping: $1,000/company

- Occupational hearing evaluations and customized hearing conservation program: $200/worker/year

- Custom hearing protection: $225/worker

With these prices in mind, we can calculate the average revenue per company serviced:

- Noise survey and mapping: $1,000

- + Occ. hearing evals./customized HCP: 250 workers x $1200 = $50,000,500

Custom hearing protection: 250 workers x $225 = $56,250

Total revenue: $107,250 per business

To cover our annual costs of $410,300 and make a marginal 10% profit, at the beginning of Year 2 we plan service 5 businesses, each with a minimum of 250 employees. Given the number of personnel, we can achieve 5 large clients by the beginning of Year 2. By the beginning of Year 3, we plan to service 12 large clients. The table shows the projected costs, revenue and profits for the first three years of business. Note that we plan to scale from 2 businesses in Year 1, to five businesses in Year 2, to 12 businesses in Year 3.

Table 9. Summary of Projected Profits for First Three Years.

Risk Analysis

As mentioned above, the number of manufacturing jobs is decreasing nationwide, but there will always be businesses that must adhere to OSHA workplace standards. As more people are exposed to damaging levels of sound, the need for education about safe listening habits and the importance of hearing protection, universal or custom, increases.29 Risks include the number of companies that will need or utilize our services being underestimated which results in less income. To limit this risk, we will market the services audiologists can provide to tailor a hearing conservation program that will reduce the number of workplace injuries. Another risk is that we underestimate the amount of growth we plan on. To reduce this risk, we will monitor our profits and workload at the end of both years one and two. Also, we could consider utilizing the Midwest Manufacturers Directory, which is a database for industrial service providers. The cost of this service is $1,241 annually and may be able to help us recruit more clients.30

Summary

Our hearing conservation business is a mobile audiology clinic that focuses on creating tailored hearing conservation programs for manufacturing businesses in Grand Rapids, Michigan. We focus on hearing loss prevention which in return helps businesses decrease the number of workplace hearing injuries they experience. This is important because businesses must comply with OSHA standards and audiologists are knowledgeable about hearing loss prevention, necessary communication on the job, and custom hearing protection. ■

References

- Rikhotso, O., Harmse, J.L. & Engelbrech, C. E. (2019). Noise Sources and Control, and Exposure Groups in Chemical Manufacturing Plants. Applied Sciences. 9. 3523. 10.3390/app9173523.

- Green (personal communication).

- Watson, R. (2020). Report finds Grand Rapids has the largest share of manufacturing jobs in US. Crain’s Grand Rapids Business. https://www.crainsgrandrapids.com/news/manufacturing/ report-finds-grand-rapids-has-largest-share-of-manufacturing-jobs-in-us/

- City of Grand Rapids. (n.d.). Manufacturing. Economic Development Department. https://growgr.grandrapidsmi.gov/Industry-Sectors/Manufacturing#:~:text=Grand%20Rapids%20is%20home%20to,office%20furniture%2C%20and%20food%20processing.

- Johnston, T. (2022). Rock out at these 11 Grand Rapids concert venues. Experience Grand Rapids. https://www.experiencegr.com/articles/post/concert-venues/

- https://www.bls.gov/opub/mlr/2021/article/exploring-midwest-manufacturing-employment-from-1990-to-2019.htm

- Arden, S., & DeCarlo, C. (2021). Exploring Midwest manufacturing employment from 1990 to 2019. Monthly Labor Review: Bureau Labor of Statistics.

- Green Nancy. (2012). Presentation at the Academy of Doctors of Audiology Annual Conference. .

- VanWyk Risk Solutions (2022). Protect workers from noise exposure with hearing conservation programs. VanWyk Risk Solutions. https://www.vanwykcorp.com/protect-workers-from-noise-exposure-with-hearing-conservation-programs/

- Kearns, S. (2019) Car wrap advertising: Is it a good investment?. QuickBooks Blog. https://quickbooks.intuit.com/r/marketing/are-vehicle-wraps-a-good-investment-for-your-small-business/

- Industry Week. (2022). IndustryWeek Contributors’ Guidelines. https://www.industryweek.com/industryweek-contributors-guidelines

- ACA Acoustics. (September 28). How much does a Noise Survey Cost?. https://www.aca- acoustics.co.uk/uncategorized/how-much-does-a-noise-survey-cost/

- Scammell, L. (2020). Hearing Conservation in the Workplace. US Compliance. https://www.uscompliance.com/blog/hearing-conservation-in-the-workplace/

- Noise–Measurement of Workplace Noise. (2020). CCOHS: Canadian Center of Occupational Health and Safety. https://www.ccohs.ca/oshanswers/phys_agents/noise/noise_measurement.html

- Dobie R. A. (2018). Cost-Effective Hearing Conservation: Regulatory and Research Priorities. Ear and hearing, 39(4), 621–630. https://doi.org/10.1097/AUD.0000000000000523

- Occupational Safety & Health Administration. (2008, June 23). OSHA Instruction. United States Department of Labor. https://www.osha.gov/enforcement/directives/04-00-004

- Lloyd-Davies, R. (2023, March 7). The Importance of Hearing Protection in the Workplace. ORBIS Environmental and Safety. https://orbisenvironmental.com/the-importance-of-hearing-protection-in-the-workplace/

- Noise at work reference from page 7

- Hearing Aid Consultants of North Mississippi. (2019). 4 Benefits of Custom Ear Protection. https://hearingoxford.com/4-benefits-of-custom-ear-protection/#:~:text=More%20effective%20ear%20protection,a%20sound%20to%20leak%20through.

- Serpanos, Y. C., Hobbs, M., Nunez, K., Gambino, L., & Butler, J. (2022). Adapting audiology procedures during the pandemic: Validity and efficacy of testing outside a sound booth. American Journal of Audiology, 31(1), 91-100.

- The True Cost of Using a Portable Audiometer (Plus a Price Comparison). eMoyo. https://blog.emoyo.tech/content/cost-of-using-a-portable-audiometer

- Whisper Room (2022). Product Catalog: Reducing sound to a whisper since 1990. https://whisperroom.com/wp-content/uploads/2022/12/WhisperRoom-Catalog-2022-Vol-29.pdf

- Industry Review. (2018). IndustryWeek. https://manufacturing.endeavorb2b.com/wp-content/uploads/sites/5/2018/10/iw_mediaguide_2018.pdf

- Urban, Brian. (2011, February 28). Interview with Brian Urban, Au.D., President, CounselEar. Audiology Online. https://www.audiologyonline.com/interviews/interview-with-brian-urban-au-1357

- Entry Level Industrial Hygienist Salary. (2023). Zip Recruiter. https://www.ziprecruiter.com/Salaries/Entry-Level-Industrial-Hygienist-Salary

- Office Staff Salary. (2023). ZipRecruiter. https://www.ziprecruiter.com/Salaries/Office-Staff-Salary

- Carpenter Bus Sales. (n.d.). Annual mini bus maintenance. Carpenter Bus Blog. https://whisperroom.com/wp-content/uploads/2022/12/WhisperRoom-Catalog-2022-Vol-29.pdf

- Bureau of Labor Statistics, U.S. Department of Labor. (2019, June 06). 43.5 percent of manufacturing workers in establishments with 250 or more workers in March 2018. https://www.bls.gov/opub/ted/2019/43-point-5-percent-of-manufacturing-workers-in-establishments-with-250-or-more-workers-in-march-2018.htm

- Carroll, Y.I., Eichwald, J., Scinicariello, F., Hoffman, H. J., Deitchman, S., Radke, M.S., Themann, C.Ll, & Breysee, P.. (2017). Vital Signs: Noise-Induced Hearing Loss Among Adults. Centers for Disease Control and Prevention: Morbidity and Mortality Weekly Report. 66(5), 139–144. DOI: http://dx.doi.org/10.15585/mmwr.mm6605e3

- Manufacturer’s News Inc. (MNI). (n.d.). Midwest manufacturers directories & manufacturing industry database. https://www.mni.net/info/midwest

- City of Grand Rapids Economic Development Department (n.d.). Manufacturing. GrowGR. https://growgr.grandrapidsmi.gov/Industry-Sectors/Manufacturing#:~:text=Grand%20Rapids%20is%20home%20to,office%20furniture%2C%20and%20food%20processing.

IndustrySelect. (2023, February 14). Top 10 Manufacturing Companies in Illinois. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-illinois#:~:text=Industrial%20Sales%20Leads%20in%20Illinois&text=An%20IndustrySelect%20subscription%20can%20put,industrial%20companies%20and%2050%2C000%20executives.

IndustrySelect. (2022, March 28). Top 10 Manufacturing Companies in Indiana. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-indiana

IndustrySelect. (2023, March 24). Top 10 Manufacturing Companies in Iowa. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-iowa

IndustrySelect. (2022, Apri 04). Top 10 Manufacturing Companies in Kansas. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-kansas

IndustrySelect. (2023, April 03). Top 10 Manufacturing Companies in Michigan. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-michigan#:~:text=Quick%20Facts%20About%20Michigan%20Manufacturing,for%20number%20of%20manufacturing%20jobs

IndustrySelect. (2022, October 08). Top 10 Manufacturing Companies in Minnesota. https://www.industryselect.com/blog/top-11-manufacturing-companies-in-minnesota

IndustrySelect. (2022, August 30). Top 10 Manufacturing Companies in Missouri. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-missouri

IndustrySelect. (2022, July 05). Top 10 Manufacturing Companies in Nebraska. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-nebraska

IndustrySelect. (2022, September 05). Top 10 Manufacturing Companies in Ohio. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-ohio#:~:text=An%20IndustrySelect%20subscription%20can%20put,industrial%20companies%20and%206%2C500%2B%20executives.

IndustrySelect. (2023, February 06). Top 10 Manufacturing Companies in South Dakota. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-south-dakota#:~:text=An%20IndustrySelect%20subscription%20can%20put,industrial%20companies%20and%204%2C500%2B%20executives.

IndustrySelect. (2023, July 25). Top 10 Manufacturing Companies in Wisconsin. https://www.industryselect.com/blog/top-10-manufacturing-companies-in-wisconsin#:~:text=Key%20Facts%20on%20Wisconsin%27s%20Manufacturing,manufacturing%20companies%20employing%20590%2C934%20workers.

Manufacturer’s News Inc. (2023). 2023 North Dakota Manufacturers Register & North Dakota Manufacturing Industry Database. https://www.mni.net/info/north-dakota-manufacturers-register

Lexi Rozycki & Kiersten Steinke are AuD students at the University of Wisconsin.